It has been about 30 years since the first ATV was introduced to the market, and since then they have become more and more popular every year. Just what is the appeal of these three and four wheel machines, could it be just the excitement that riding them creates? Nowadays you will find entire families enjoying the excitement and riding as a family activity. But there is always down sides to things, and riding ATVs is no different. Many accidents happen each year to people riding ATVs, keeping a few things in mind and following some simple safety procedures could keep you in the safe zone at all times.

It has been about 30 years since the first ATV was introduced to the market, and since then they have become more and more popular every year. Just what is the appeal of these three and four wheel machines, could it be just the excitement that riding them creates? Nowadays you will find entire families enjoying the excitement and riding as a family activity. But there is always down sides to things, and riding ATVs is no different. Many accidents happen each year to people riding ATVs, keeping a few things in mind and following some simple safety procedures could keep you in the safe zone at all times.

One of the first rules that you will want to follow is as a new rider, always head out to the trails with an experienced rider, in fact even an experienced rider should always have a partner with them. If at all possible before you buy your own ATV rent one or use a friends to see if this is something that you are really going to like. Once you determine that you enjoy the hobby, then start recording what type of riding you like to do and what trails you will be frequenting the most.

It is usually recommended that beginners not go off and buy a new ATV, rather become familiar with the sport first, try out some different style machines such as utility ATV’s or Sport ATV’s and determine what feels most comfortable to you. After you get your first machine it is always advisable to take a safety course. You can find ATV safety courses that will meet once a week for a couple of hours that is spread out three or four weeks. Not only will they review basic safety precautions, but you will also learn fundamental maintenance for your vehicle, like how to change the Yamalube 2S oil. This is not mandatory, but I believe is well worth your time and money.

Did you like this? Share it:

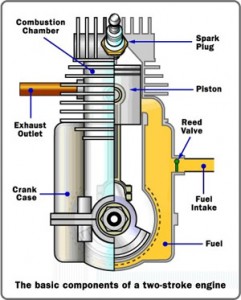

The carburetor is one of the most vital components of any two-stroke engine, as it works to blend the air, fuel, and outboard motor oil so that they can be utilized in the stroke cycle. For many owners of two-stroke engines, however, carburetor maintenance and mechanical issues are a headache. The next few days we will go over the basics for making routine adjustments to the carburetor.

The carburetor is one of the most vital components of any two-stroke engine, as it works to blend the air, fuel, and outboard motor oil so that they can be utilized in the stroke cycle. For many owners of two-stroke engines, however, carburetor maintenance and mechanical issues are a headache. The next few days we will go over the basics for making routine adjustments to the carburetor.

Now that we have overviewed the inner workings of a two-stroke engine, the advantages should be ascertainable. The consolidation of the stroke cycle allows for a more rudimentary and lightweight design, which also produces more power. This combination makes two-stroke engines ideal for various handheld equipment and small vehicles. With these obvious advantages, some may be wondering why two-stroke engines aren’t used in cars and other large vehicles.

Now that we have overviewed the inner workings of a two-stroke engine, the advantages should be ascertainable. The consolidation of the stroke cycle allows for a more rudimentary and lightweight design, which also produces more power. This combination makes two-stroke engines ideal for various handheld equipment and small vehicles. With these obvious advantages, some may be wondering why two-stroke engines aren’t used in cars and other large vehicles. Yesterday we overviewed the main process that takes place in the cycle of a two-stroke engine. Now we are going to breakdown this process a little further to better understand what is occurring in this process. When the piston is working in its cycle, the crankshaft will give the piston momentum so that it can return to the spark plug for the compression stroke. During this process the piston compresses the mixture of

Yesterday we overviewed the main process that takes place in the cycle of a two-stroke engine. Now we are going to breakdown this process a little further to better understand what is occurring in this process. When the piston is working in its cycle, the crankshaft will give the piston momentum so that it can return to the spark plug for the compression stroke. During this process the piston compresses the mixture of  Yesterday we overviewed some of the basics differences between four and two-stroke motors. Today we will go over some of the mechanical operations of the engine. A two-stroke engine is essentially a simplified version of the four-stroke, and this means that the cycle is more economical and many of the operations are consolidated. As we said previously, one of the biggest differences is that the spark plug fires once every revolution, as opposed to every other revolution.

Yesterday we overviewed some of the basics differences between four and two-stroke motors. Today we will go over some of the mechanical operations of the engine. A two-stroke engine is essentially a simplified version of the four-stroke, and this means that the cycle is more economical and many of the operations are consolidated. As we said previously, one of the biggest differences is that the spark plug fires once every revolution, as opposed to every other revolution.

Most outboard motors will run fine for years with little or no attention. If you notice that your outboard motor is running at a slow speed or idle problem then you should consider getting a major tune which includes:

Most outboard motors will run fine for years with little or no attention. If you notice that your outboard motor is running at a slow speed or idle problem then you should consider getting a major tune which includes: It has been about 30 years since the first ATV was introduced to the market, and since then they have become more and more popular every year. Just what is the appeal of these three and four wheel machines, could it be just the excitement that riding them creates? Nowadays you will find entire families enjoying the excitement and riding as a family activity. But there is always down sides to things, and riding ATVs is no different. Many accidents happen each year to people riding ATVs, keeping a few things in mind and following some simple safety procedures could keep you in the safe zone at all times.

It has been about 30 years since the first ATV was introduced to the market, and since then they have become more and more popular every year. Just what is the appeal of these three and four wheel machines, could it be just the excitement that riding them creates? Nowadays you will find entire families enjoying the excitement and riding as a family activity. But there is always down sides to things, and riding ATVs is no different. Many accidents happen each year to people riding ATVs, keeping a few things in mind and following some simple safety procedures could keep you in the safe zone at all times. The first snowmobile-esque vehicle to be manufactured was intended for military and police transportation. In the mid to late ’50s, Bombardier created a rudimentary snow track machine capable of holding up to a dozen people. Needless to say, this machine bore little resemblance to the sleek, sporty recreational sleds of today. Bombardier released a more compact snowmobile in 1959; for the first time, such a machine was meant for public use.

The first snowmobile-esque vehicle to be manufactured was intended for military and police transportation. In the mid to late ’50s, Bombardier created a rudimentary snow track machine capable of holding up to a dozen people. Needless to say, this machine bore little resemblance to the sleek, sporty recreational sleds of today. Bombardier released a more compact snowmobile in 1959; for the first time, such a machine was meant for public use. In the past few days our discussion of snowmobiles has run the gamut from power systems to track mechanics and steering. Today, it’s time to take a step back from the nuts and bolts to see the forest for the trees. Just what are the environmental implications of recreational sleds, and what plans are in the works to increase engine efficiency? Unlike the environmental effects of automobiles and boats, those of snowmobiles remain understudied and to some extent uncertain.

In the past few days our discussion of snowmobiles has run the gamut from power systems to track mechanics and steering. Today, it’s time to take a step back from the nuts and bolts to see the forest for the trees. Just what are the environmental implications of recreational sleds, and what plans are in the works to increase engine efficiency? Unlike the environmental effects of automobiles and boats, those of snowmobiles remain understudied and to some extent uncertain. Over the last few days, we’ve discussed the ins and outs of a seasonal snowmobile tune-up – from salvaging the upholstery to checking for exterior scratches and ensuring proper fluid levels. In today’s final installment, we’ll shift over to one of the most common causes of engine failure: the filthy carburetor. It doesn’t take much more than regular hand tools, a can of carb cleaner, some ingenuity and a willingness to get your hands dirty.

Over the last few days, we’ve discussed the ins and outs of a seasonal snowmobile tune-up – from salvaging the upholstery to checking for exterior scratches and ensuring proper fluid levels. In today’s final installment, we’ll shift over to one of the most common causes of engine failure: the filthy carburetor. It doesn’t take much more than regular hand tools, a can of carb cleaner, some ingenuity and a willingness to get your hands dirty. Today we pick up right where we left off in our preseason snowmobile maintenance process: the visual inspection. Having checked for cracks in the hood, we now turn our attention to the upholstery. Seat covers may become nicked and scratched with use, and in some cases they might slip right off the mounting. These details might seem trivial or superficial, and it’s true that your snow machine can operate no matter the state of the seating. Now is a good time to shore up any aesthetic flaws, however. Try gluing a similar fabric underneath hole in the leather or synthetic seating.

Today we pick up right where we left off in our preseason snowmobile maintenance process: the visual inspection. Having checked for cracks in the hood, we now turn our attention to the upholstery. Seat covers may become nicked and scratched with use, and in some cases they might slip right off the mounting. These details might seem trivial or superficial, and it’s true that your snow machine can operate no matter the state of the seating. Now is a good time to shore up any aesthetic flaws, however. Try gluing a similar fabric underneath hole in the leather or synthetic seating. Now that November’s icy chill has replaced any thoughts of summertime fun, many outdoors enthusiasts are putting their boats away for winter. We’ve discussed proper winterization techniques in the past, but now it’s time to focus on an equally invigorating recreational pastime: snowmobiling. No matter your preferred outdoor pursuit, it’s important to conduct a preseason checkup.

Now that November’s icy chill has replaced any thoughts of summertime fun, many outdoors enthusiasts are putting their boats away for winter. We’ve discussed proper winterization techniques in the past, but now it’s time to focus on an equally invigorating recreational pastime: snowmobiling. No matter your preferred outdoor pursuit, it’s important to conduct a preseason checkup.