Snowmobile Storage: Part Two

The first thing to do when storing your sled is to wash and wax every inch. While this may seem like an unnecessary and purely aesthetic routine, this will help protect the paint job and the body of the vehicle. Once this is done, give the sled a quick onceover to find any chips or cracks, and it is advisable to paint the ski bottoms as well.

The first thing to do when storing your sled is to wash and wax every inch. While this may seem like an unnecessary and purely aesthetic routine, this will help protect the paint job and the body of the vehicle. Once this is done, give the sled a quick onceover to find any chips or cracks, and it is advisable to paint the ski bottoms as well.

Now that the body is done, it is time to move on to the engine. Start up your snowmobile and pull on the oil pump cable to allow your 2 cycle oil to circulate through the entire system. Next, you want to fill the fuel tank completely, which will eliminate air space in the tank and ensure that condensation can’t form.

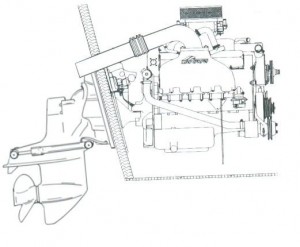

Since their introduction in the early 1900s, outboard motors have revolutionized the way in which we think about boating. Prior to that, boaters and fishermen were largely dependent on the direction of wind or – for those who felt like using oars – brute force. Outboards have taken the focus of our attentions of locomotion, allowing us to think about catching fish or just enjoy the scenery.

Since their introduction in the early 1900s, outboard motors have revolutionized the way in which we think about boating. Prior to that, boaters and fishermen were largely dependent on the direction of wind or – for those who felt like using oars – brute force. Outboards have taken the focus of our attentions of locomotion, allowing us to think about catching fish or just enjoy the scenery. Today we conclude our week-long look at snowmobiles. It all began Monday with an exploration of a typical sled’s drive system. From there, we compared and contrasted snowmobile tracks with those of a tank. Yesterday we posted some brief thoughts on the environmental impact of snowmobiling and the importance of replenishing

Today we conclude our week-long look at snowmobiles. It all began Monday with an exploration of a typical sled’s drive system. From there, we compared and contrasted snowmobile tracks with those of a tank. Yesterday we posted some brief thoughts on the environmental impact of snowmobiling and the importance of replenishing  In yesterday’s installment, we took a look at the four main components of a snowmobile’s drive system: the engine, clutch, track and skis. We’ll shift gears slightly today to focus on the track in particular and the steering system in general. The track is designed to maximize traction as the sled moves along the snow. It could be likened to that of a tank, with one major difference: tank tracks are stiff and durable above all other considerations because of the role they play in warfare. Snowmobile tracks, on the other hand, are meant for optimal swiftness and maneuverability.

In yesterday’s installment, we took a look at the four main components of a snowmobile’s drive system: the engine, clutch, track and skis. We’ll shift gears slightly today to focus on the track in particular and the steering system in general. The track is designed to maximize traction as the sled moves along the snow. It could be likened to that of a tank, with one major difference: tank tracks are stiff and durable above all other considerations because of the role they play in warfare. Snowmobile tracks, on the other hand, are meant for optimal swiftness and maneuverability. Buying an outboard motor is a process that should not be taken lightly. As perhaps the most critical purchase you’ll ever make in regards to your boat, it deserves significant preparation and forethought. Take some time to explore the market – both online and at nearby dealerships. Scan the classified ads in your local newspaper for used outboards, but remember that most marine engines manufactured since 1990 should receive TC-W3 certified

Buying an outboard motor is a process that should not be taken lightly. As perhaps the most critical purchase you’ll ever make in regards to your boat, it deserves significant preparation and forethought. Take some time to explore the market – both online and at nearby dealerships. Scan the classified ads in your local newspaper for used outboards, but remember that most marine engines manufactured since 1990 should receive TC-W3 certified  Yesterday we discussed the virtues of purchasing the proper propeller for one’s small boat. I received some correspondence from some longtime readers requesting specifics. The most common questions had to do with the “pitch” of the propeller and what that might mean for engine efficiency. So, thanks to popular demand, let’s take a closer look at that undervalued part that cuts through the water with authority.

Yesterday we discussed the virtues of purchasing the proper propeller for one’s small boat. I received some correspondence from some longtime readers requesting specifics. The most common questions had to do with the “pitch” of the propeller and what that might mean for engine efficiency. So, thanks to popular demand, let’s take a closer look at that undervalued part that cuts through the water with authority. If fuel efficiency and thrift are important to you – and let’s face it, most small boat owners are a bit hard up for cash these days – consider thinking outside the box. We’ve sung the virtues of fuel flow meters, marine GPS units and routine maintenance habits, all of which will help you save on fuel and maximize your fishing or cruising experience. Still, these are far from the only serious steps a money-savvy boat owner can take to cut down on costs. For instance, make sure you choose a

If fuel efficiency and thrift are important to you – and let’s face it, most small boat owners are a bit hard up for cash these days – consider thinking outside the box. We’ve sung the virtues of fuel flow meters, marine GPS units and routine maintenance habits, all of which will help you save on fuel and maximize your fishing or cruising experience. Still, these are far from the only serious steps a money-savvy boat owner can take to cut down on costs. For instance, make sure you choose a

Today’s boaters could be forgiven for putting the past out of mind. As recently as the 1990s, federal rules for outboard engine efficiency were much less stringent – to the point that pollution became a problem and the small boating industry became something of a scapegoat for environmental groups. Around 1996, the marine industry and the Environmental Protection Agency teamed up to create and enforce fuel standards.

Today’s boaters could be forgiven for putting the past out of mind. As recently as the 1990s, federal rules for outboard engine efficiency were much less stringent – to the point that pollution became a problem and the small boating industry became something of a scapegoat for environmental groups. Around 1996, the marine industry and the Environmental Protection Agency teamed up to create and enforce fuel standards.

Over the last few months, we’ve visited and revisited the threat posed by ethanol additives to the small boat industry. Specifically, ethanol lobbyists are seeking a waiver to sell E15 – that’s gas with a 15 percent concentration of ethanol – or even E20 as a standard fuel mixture for marine engines. As many boaters are aware, most small vessels on the market and in the water today are ill-equipped to deal with such high concentrations of the additive.

Over the last few months, we’ve visited and revisited the threat posed by ethanol additives to the small boat industry. Specifically, ethanol lobbyists are seeking a waiver to sell E15 – that’s gas with a 15 percent concentration of ethanol – or even E20 as a standard fuel mixture for marine engines. As many boaters are aware, most small vessels on the market and in the water today are ill-equipped to deal with such high concentrations of the additive.